Knitted terry fabric is weft knitted fabric. Due to the characteristics of its fabric, the defects are mostly raw materials and holes, and some of them are also dissected on the fabric inspection machine (fabric inspection machine is different from machine knitting), and it is rolled.

Weaving fabric is a kind of cloth made by interweaving yarn vertically from two directions of warp and weft. The longitudinal yarn is called warp yarn and the transverse yarn is called weft yarn. Woven fabric is a sheet fabric made of warp and weft yarn interwoven vertically on the loom according to certain rules. For example (plain, twill, satin, etc., all woven)

What’s the difference between knitted terry and woven cloth ?

Knitted terry fabrics and woven fabrics have their own unique characteristics in processing technology, fabric structure, fabric characteristics and use of finished products because of their different methods of weaving.

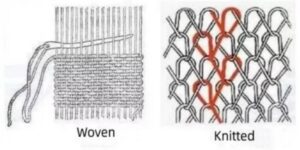

I.Composition of fabric organization

a) Knitted terry fabric: fabric is formed by the yarn is bent into coils in sequence, and the coils are interlocking with each other. The process of yarn forming coils can be carried out horizontally or vertically. The horizontal knitting is called weft knitting fabric, while the longitudinal knitting is called warp knitting fabric.

b) Woven fabric: Fabric consisting of two or more groups of mutually perpendicular yarns interwoven at a 90 degree Angle for warp and weft. The longitudinal yarns are called warp yarns and the transverse yarns are called weft yarns.

Ⅱ. Basic unit of fabric organization

a)Knitted terry fabric: the coil is the smallest basic unit of knitted fabric, and the coil consists of a spatial curve of the loop stem and the extension line.

b) Woven fabric: Each point of intersection between the warp and weft is called a tissue point and is the smallest basic unit of woven fabric.

Leave A Comment