Coating printing refers to paint pigments (this is called pigment rather than dye, because it is granular.) It cannot react directly with cellulose fibers, and it needs to have an intermediate is a binder to make it stick to the fabric.So you can imagine that the binder plays a role of glue.

So this kind of printed fabric will feel a little hard, and because it is stuck on it, it is possible to pass many times of washing, many times of friction, the pigment particles will fall off to different degrees, the fabric is faded.

Advantages: simple process, high productivity, low cost, less pollution.Printing lines clear, easy to color, a wide range of applications, can be used for a variety of fabrics.

Disadvantages: hard hand, poor fastness to dry wear and wet rubbing, poor air permeability of large-area printing, color brilliance is not as good as active printing.

Ⅱ)Reactive Printing:

Reactive printing refers to the printing process of the fabric pattern with reactive dye. The so-called reactive dye refers to the dye molecules with reactive groups. This dye can react with cellulose fiber (cotton fiber), so the color is stronger.

This method of printing and dyeing requires a lot of washing, so the fabric feels softer, because most reactive dyes react with the fibers, so there is no real dye on the fabric, more environmentally friendly and safer.The color of this fabric theoretically won’t fade no matter how many times you wash it

Advantages: variety, bright color, good color fastness, good hand feel, low environmental formaldehyde content, not easy to fade after washing.

Disadvantages: the dye utilization rate is poor, the production process produces a lot of sewage, easy to stick color, high energy consumption and high cost.

Active printing has many advantages, but in the round screen printing, the line fineness of active printing is not as good as coating printing, reactive dye penetration is poor, printing pattern can only use a relatively large mesh of low mesh net, the line and fine pattern control is poor.Active printing can only achieve 25 silk (2.5mm) thickness lines, coating printing line fineness can reach 15 silk (1.5mm).

Therefore, some active printing patterns will also adopt the process of active/coating joint printing, that is, large areas of color with active printing, small patterns or fine lines with coating printing, so as to ensure the clarity of the pattern and ensure the feel of the fabric.

Ⅲ)Four ways to identify active printing and coating printing:

1. Look at the color: the color of the paint printing is not bright, the color is dark, giving a person a feeling that the color is floating on the cloth.

2. Look at the gloss: general coating printing cloth before leaving the factory are through the “calendering” process, to cover the shortcomings of the cloth surface is not smooth, so if you see the cloth surface has a sense of gloss, it may be the coating printing.The finish, which is obtained by calendering, is disposable and disappears after washing.

3. Smell: coating printing adds a lot of adhesives, and it is directly finalized without washing, so there will be a strong smell in the finished fabric.

4. Touch: Paint printing feels hard, but it may not work.This is because, cloth business is to cover this shortcoming, in finalize the design when added a lot of softener, and finished product passes “calender” after feel also can again some softer.But most of the softener will come off after washing.

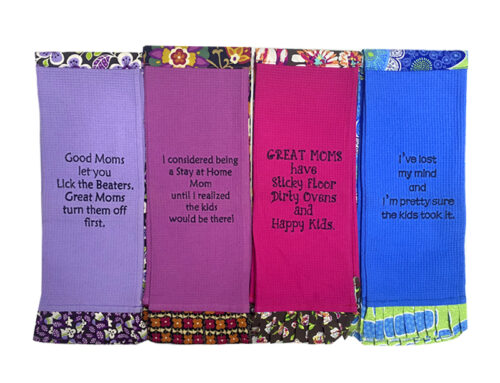

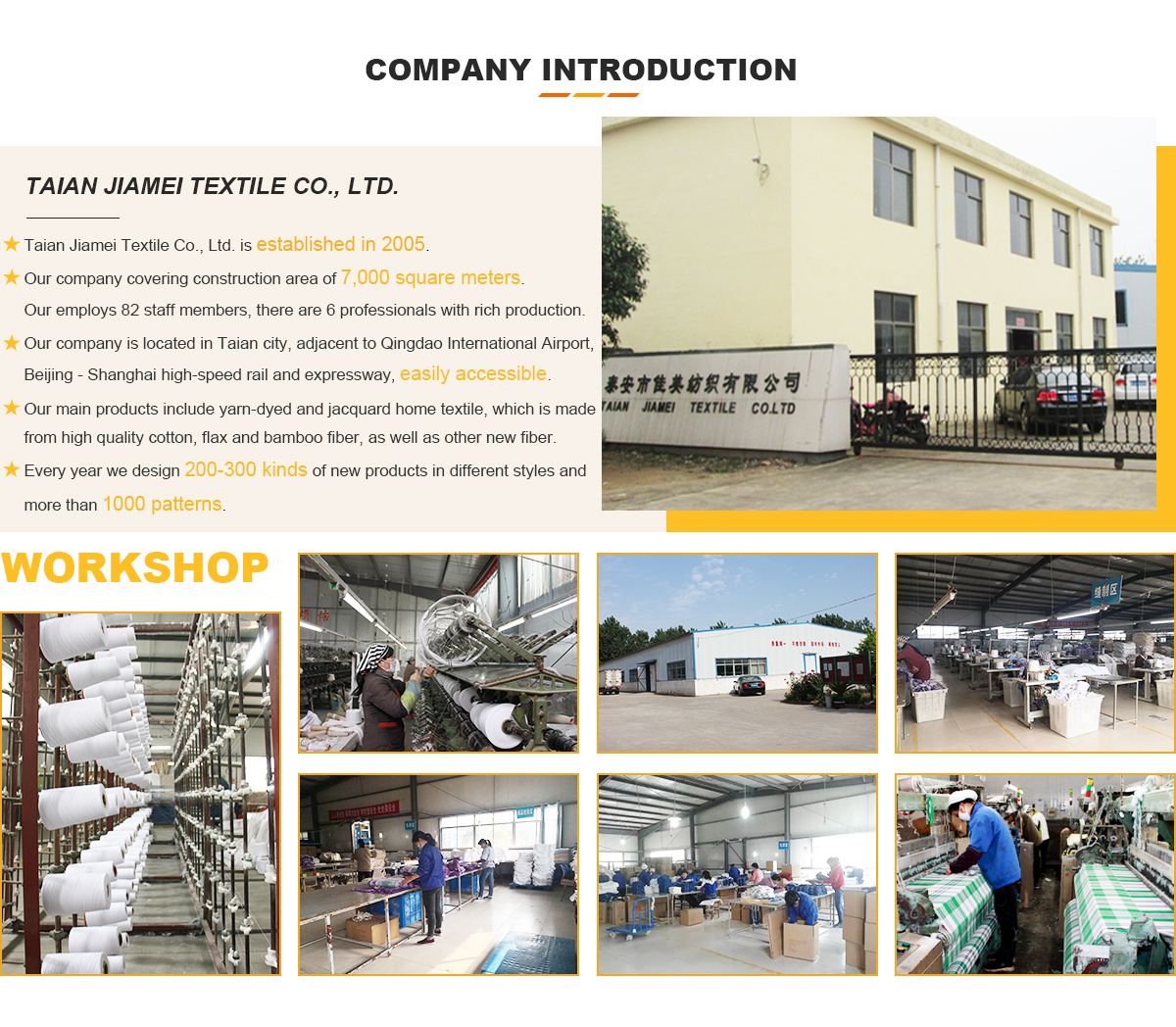

JIAMEI Textile can manufacture according to your special requirements with customized materials, sizes, weights and colors, etc. Your logo can be printed or embroidered or Jacquard on the towel products such as kitchen towels, tea towels, dish towels, Turkish towel,beach towel and bath towel.

We have recently passed BSCI, CE, OEKO, STEP and other certifications.

As you can see, we are factory, we have our own sales team too, we can control the quality by ourselves, All our products have excellent quality, shorter delivery time and competitive price.so that we have many trade company customer too.

Hope to be your business partners.